"And is just like that! No epoxy or nothing to worry about. Nice and dry, but quick. Easy!" - Dave, Haydn+Rollett

“We are pretty impressed with these PYTHONs, super easy to install and fast delivery turnaround, no downtime onsite“ — Peter, D Stevens Ltd Building Contractors

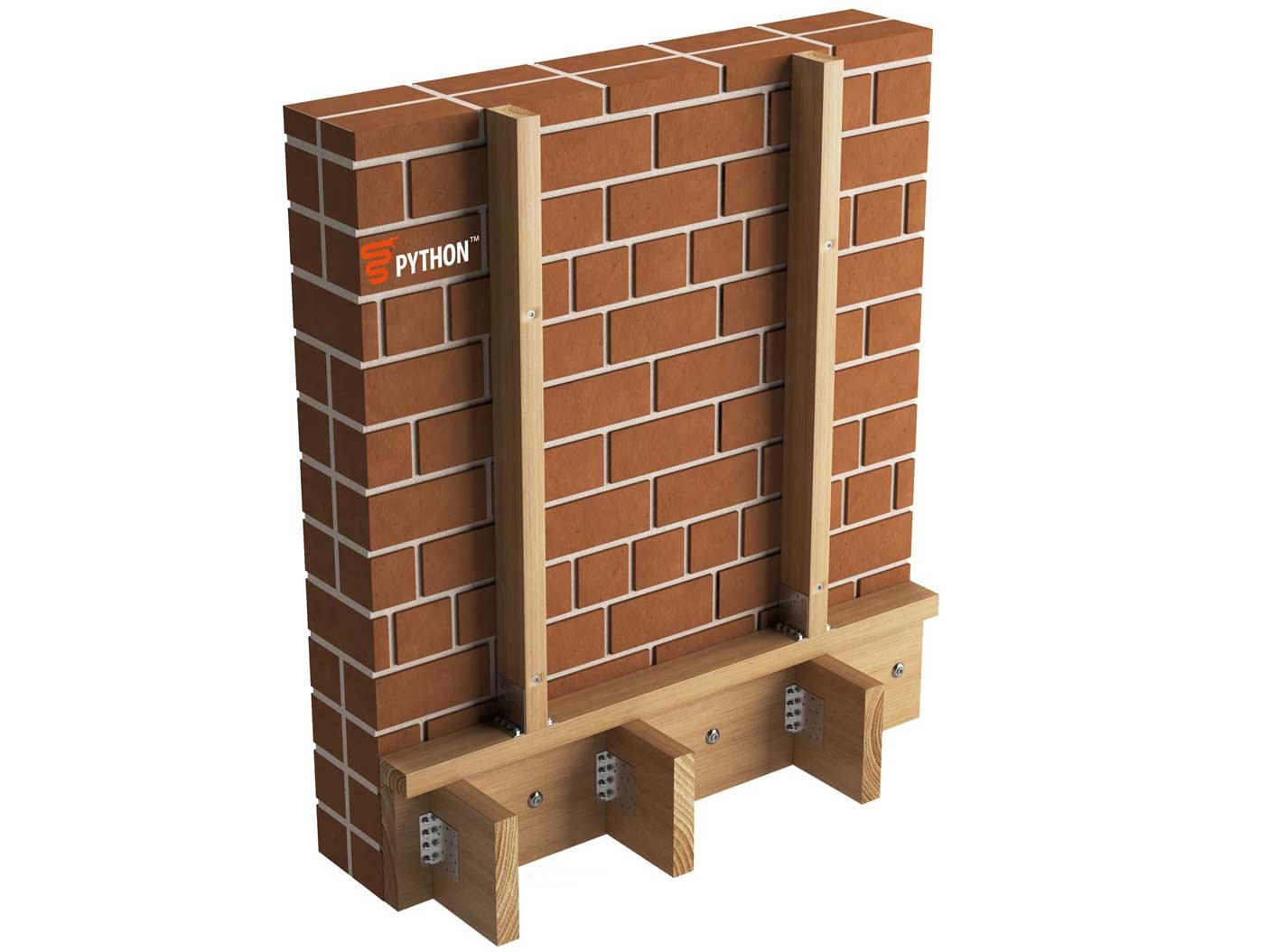

PYTHON MT Fixings are a purposely designed, seismically tested and fully mechanical structural system for connecting steel and timber members onto brick, concrete block and soft stone masonry.

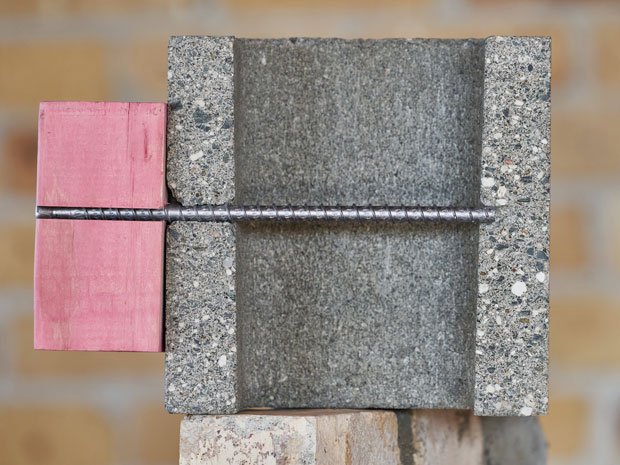

The PYTHON MT is extensively tested in a wide range of New Zealand substrate materials. PYTHON MT fixings have opened doors to a wide range of structural solutions that were previously considered impractical or too costly to implement.

Minimally invasive and fully reversible, the PYTHON MT offers a mechanical structural connection to masonry that is quick, simple, and reliable.

APPLICATIONS

Reliable alternative to epoxy anchorages into masonry and URM.

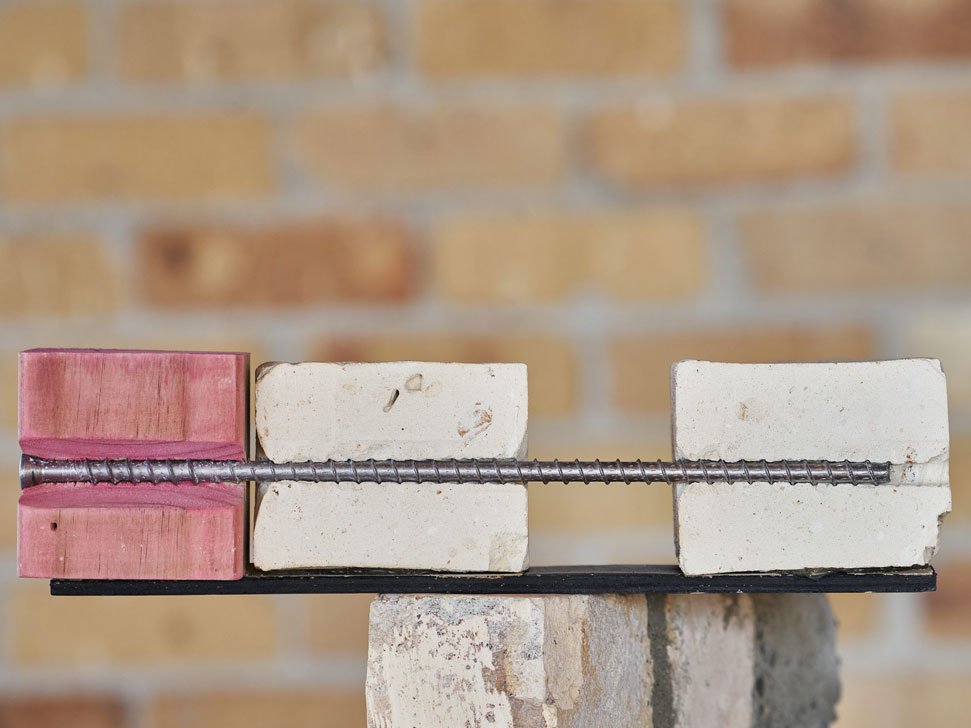

Structural connections between timber or steel members and URM or CMU masonry.

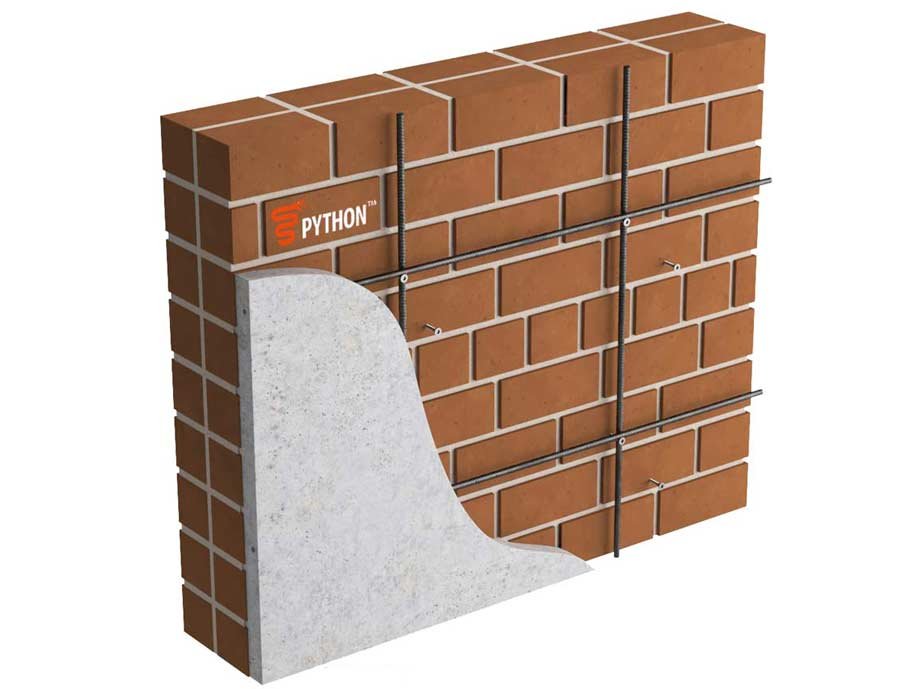

Starter studs for new shotcrete or concrete overlays, floors, and foundations.

Masonry wall to floor/roof connections.

Timber or steel strong-backs onto URM and CMU.

Steel portal or moment frames.

Plywood or CLT panel overlays.

Parapet or roof frame tie down.

Wide range of other applications, including earthquake strengthening.

FEATURES

High tension and shear capacity in a variety of masonry and URM substrates.

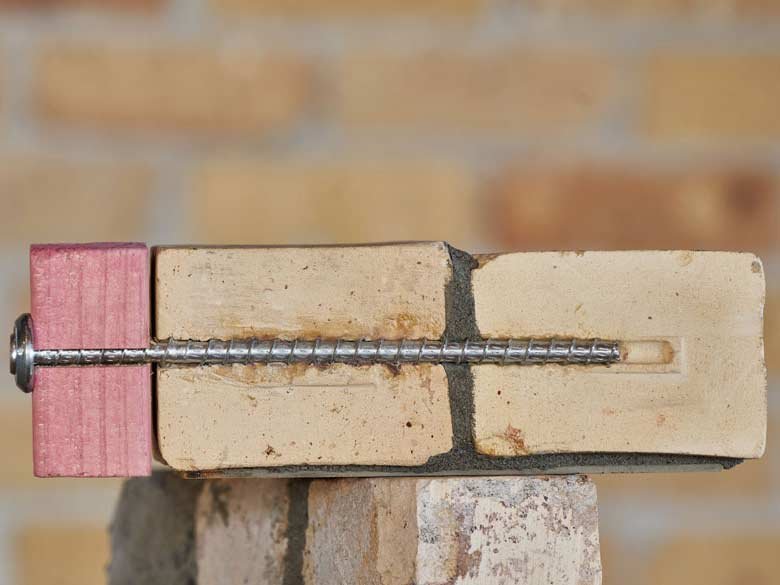

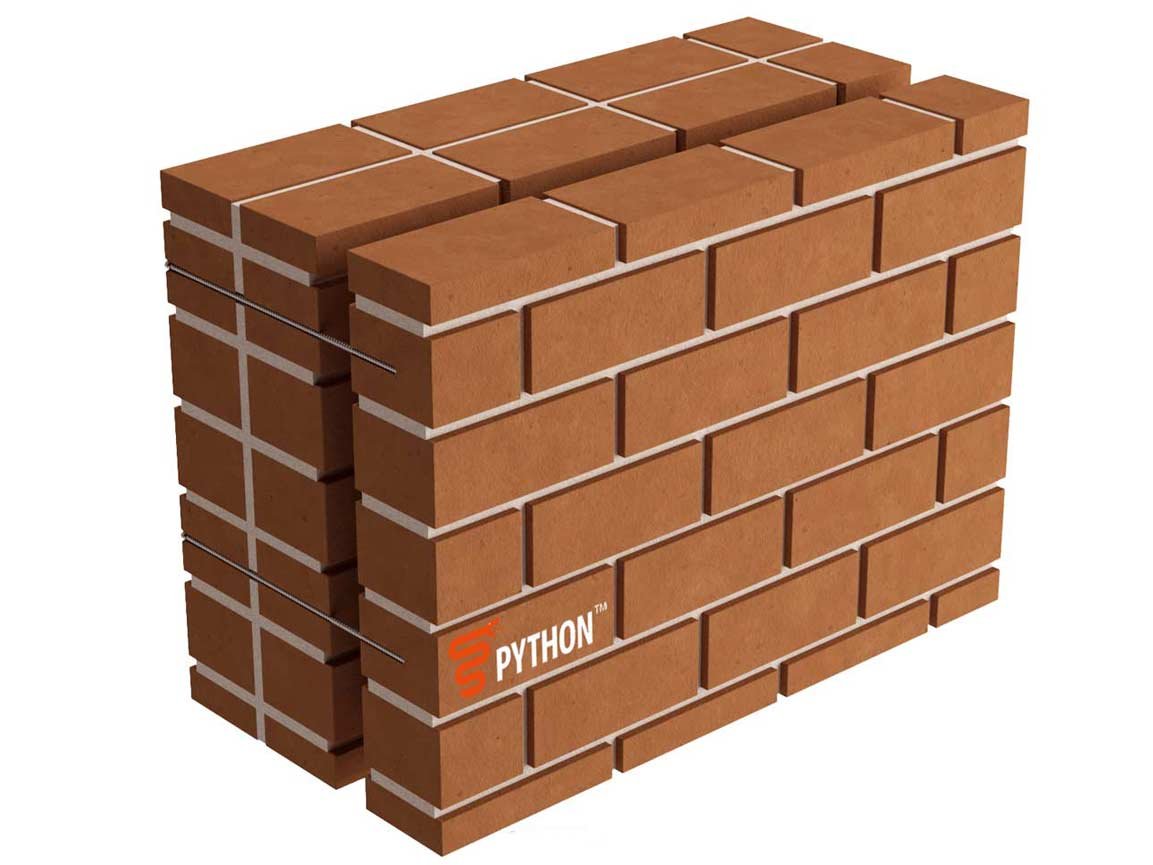

Cuts through brick on rotation for a strong and reliable mechanical bond.

Duel thread design for increased capacity in timber applications.

Dry installation, no epoxy required.

Fast installation with no specialised tools or skills needed.

Truly versatile range of applications.

Technical

Nominal shank diameter Ø 8 mm with total length of 160, 230, 340 mm - Customised lengths up to 1200mm long are available on request.

Zinc-Nickel coating, R4 (external, coastal environments) durability classification in accordance with AS/NZS 2699.1 & AS 3700. Tested in accordance with ASTM B117:2019 to 1500 hours of salt spray exposure (Read more).

Technical engineering design data tested for a range of substrates available (Read more).

Example construction details available (Request).

On-site quality assurance proof testing on request (Contact us).